As the world continues to advance technologically and address pressing global challenges, the field of materials science remains a cornerstone of innovation. New materials are critical for industries ranging from aerospace and automotive to healthcare and renewable energy. The year 2025 is poised to mark significant progress in the development, application, and commercialization of cutting-edge materials. This article explores the key trends shaping the future of new materials in 2025, focusing on advancements in technology, sustainability, market demands, and societal .

1. Increased Focus on Sustainability

Sustainability has become a defining factor in the development of new materials. As industries face mounting pressure to reduce their environmental footprint, researchers and companies are prioritizing sustainable solutions.

1.1 Biodegradable and Renewable Materials

One of the most notable trends is the development of biodegradable polymers and renewable materials.

- Bioplastics: Polymers derived from natural sources such as cornstarch and algae are gaining traction as replacements for traditional plastics.

- Renewable Composites: Materials made from agricultural by-products or recycled fibers are being adopted in packaging and construction.

1.2 Circular Economy Principles

The push for a circular economy is driving innovation in recyclable materials and design-for-recycling approaches.

- Recyclable Composites: Researchers are developing composites that maintain performance while being easily separated for recycling.

- Closed-Loop Processes: Industrial processes are being optimized to minimize waste and reuse by-products.

1.3 Low-Carbon Manufacturing

Sustainability in manufacturing is another key trend.

- Green Chemistry: Using non-toxic chemicals and renewable feedstocks in material synthesis.

- Energy-Efficient Production: Innovations such as additive manufacturing and low-temperature processing are reducing energy consumption.

2. Advancements in Smart Materials

Smart materials, which can respond to external stimuli, continue to evolve, enabling new applications across industries.

2.1 Self-Healing Materials

Materials with self-healing properties are becoming more sophisticated and commercially viable.

- Applications: Self-healing polymers are being integrated into coatings, electronics, and construction materials.

- Mechanisms: Advances in microcapsules, reversible bonds, and dynamic covalent chemistry are enhancing self-healing capabilities.

2.2 Shape-Memory Alloys and Polymers

Shape-memory materials that revert to their original form after deformation are seeing broader adoption.

- Industries: These materials are critical for robotics, aerospace.

- Innovations: Improvements in thermal and electrical triggering mechanisms are expanding their functionality.

2.3 Piezoelectric and Thermoelectric Materials

Energy-harvesting materials are becoming integral to powering small devices and sensors.

- Piezoelectric Materials: Used in sensors, wearable devices, and energy-harvesting applications.

- Thermoelectric Materials: Enabling waste heat recovery and efficient power generation in industrial settings.

3. Nanomaterials Revolution

Nanomaterials continue to dominate the landscape of advanced materials due to their exceptional properties and versatility.

3.1 Graphene and Beyond

Graphene remains a prominent material, but other two-dimensional materials are also gaining attention.

- Applications: Electronics, batteries, and thermal management solutions.

- Emerging 2D Materials: Transition metal dichalcogenides (TMDs) and boron nitride are being explored for specialized applications.

3.2 Nanocomposites

Nanocomposites are being tailored for high-performance applications.

- Lightweight Strength: Used in aerospace and automotive industries for weight reduction.

- Thermal Conductivity: Enhancing heat dissipation in electronics and energy systems.

4. Advanced Composites for High-Performance Applications

Composites are evolving to meet the demands of modern industries, offering superior properties and performance.

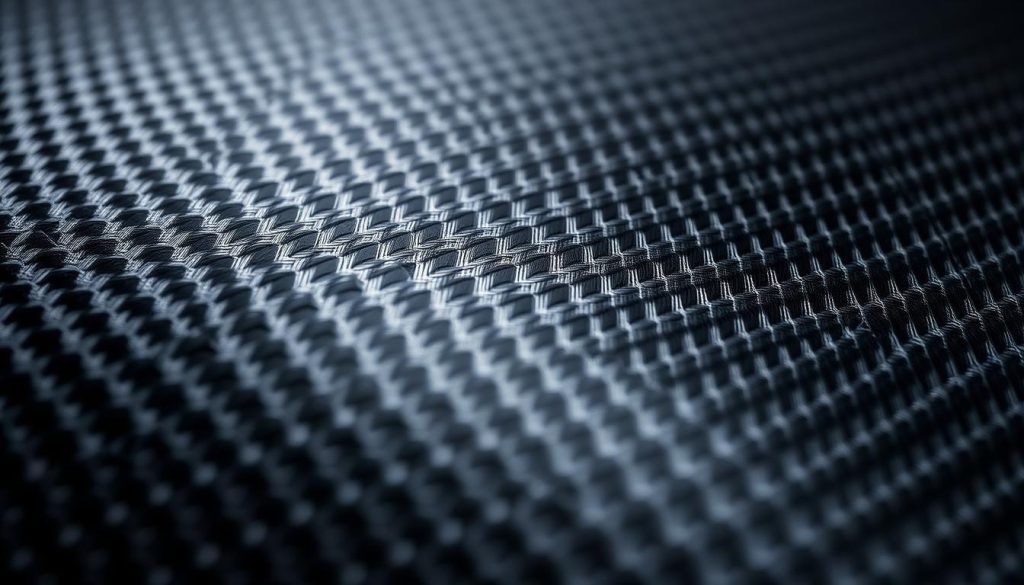

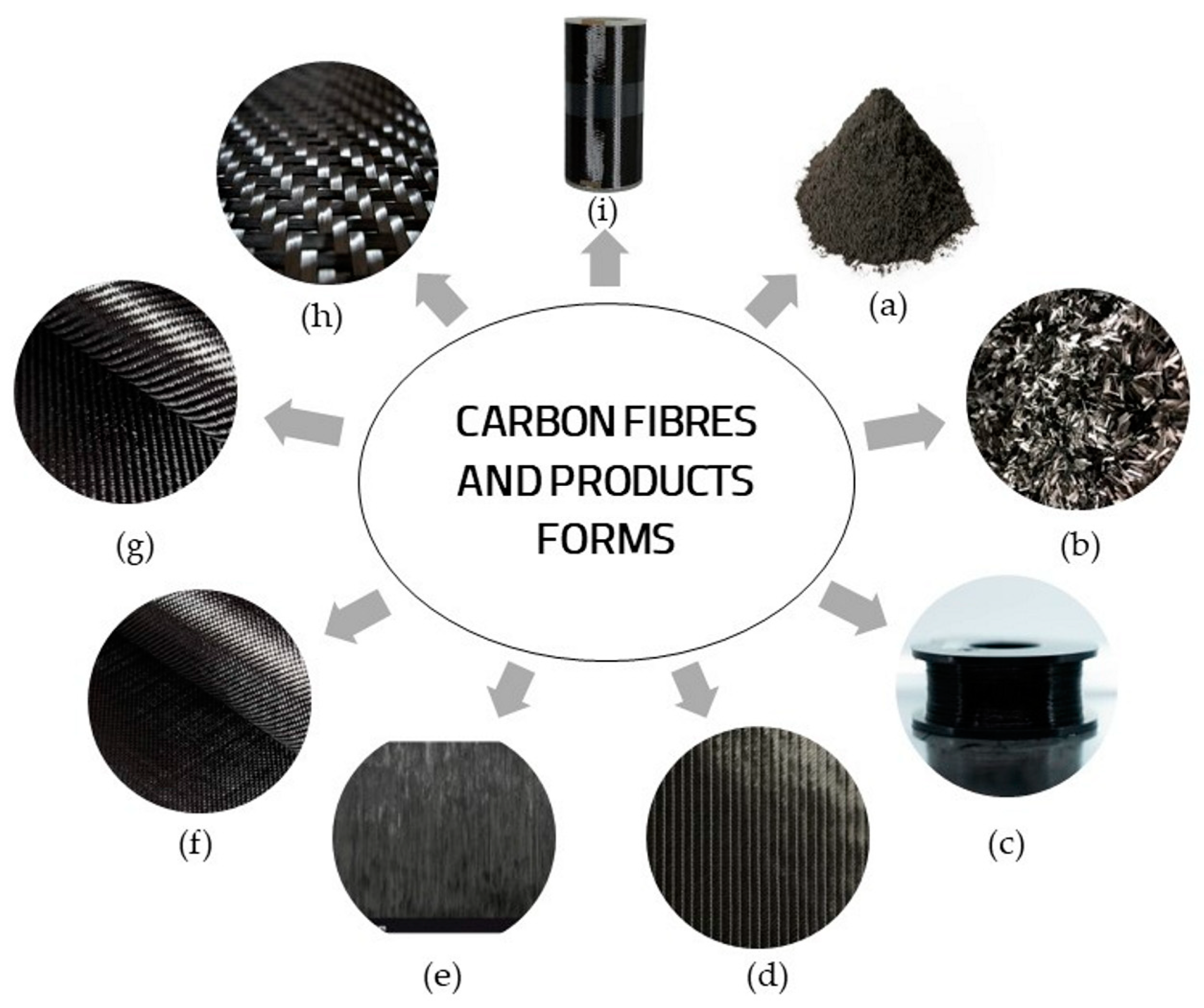

4.1 Carbon Fiber Reinforced Polymers (CFRPs)

CFRPs continue to dominate in aerospace and automotive sectors.

- Lightweight Advantage: Essential for fuel efficiency and performance.

- Recycling Challenges: Research is addressing the recyclability of CFRPs.

4.2 Ceramic Matrix Composites (CMCs)

CMCs are gaining popularity for high-temperature and structural applications.

- Industries: Used in jet engines, gas turbines, and industrial processes.

- Properties: Superior thermal resistance and mechanical strength.

4.3 Bio-Based Composites

Combining performance with sustainability, bio-based composites are entering mainstream markets.

- Applications: Packaging, construction, and automotive interior components.

5. Digital Integration and Material Informatics

The integration of digital tools and material informatics is transforming the way materials are discovered and optimized.

5.1 Artificial Intelligence (AI) in Materials Science

AI is accelerating the discovery and design of new materials.

- Predictive Models: Machine learning algorithms predict material properties and performance.

- High-Throughput Experiments: Automating synthesis and testing for faster development cycles.

5.2 Digital Twins

Digital twins of materials are enabling simulation and optimization.

- Applications: Virtual testing of materials under various conditions.

- Benefits: Reducing the cost and time associated with physical prototyping.

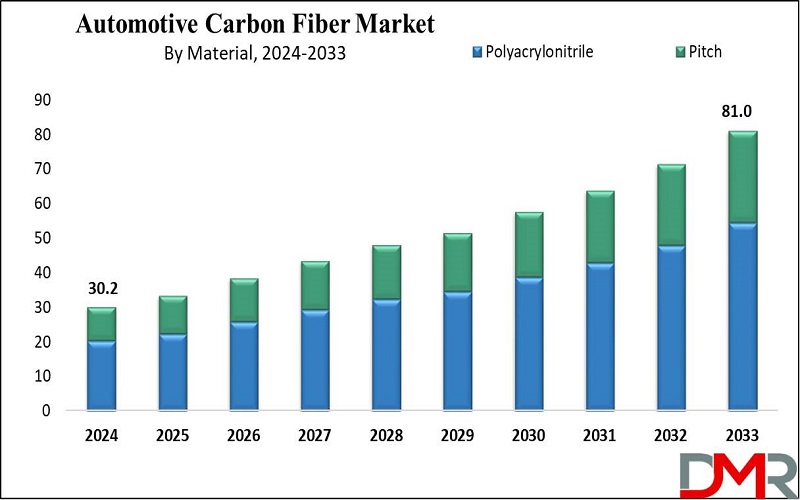

6. Market Trends and Industrial Applications

Market demands are shaping the development and adoption of new materials.

6.1 Energy and Sustainability

Materials for renewable energy systems and energy storage are in high demand.

- Battery Materials: Solid-state electrolytes and advanced cathodes for next-generation batteries.

- Solar Panels: High-efficiency perovskite and tandem solar cells.

6.3 Transportation and Mobility

Lightweight and high-performance materials are critical for the transportation sector.

- Electric Vehicles (EVs): Materials that improve range and efficiency.

- Aerospace: Reducing weight while maintaining structural integrity.

7. Challenges and Future Outlook

Despite the promise of new materials, challenges remain in scaling, cost, and societal acceptance.

7.1 Scalability and Cost

Scaling up production while maintaining quality and affordability is a major hurdle.

7.2 Environmental and Ethical Concerns

Addressing the full lifecycle of new materials, including mining and disposal.

7.3 Interdisciplinary Collaboration

The future of materials science will depend on collaboration across disciplines and industries.

Conclusion

The development trends of new materials in 2025 reflect a dynamic intersection of technology, sustainability, and innovation. With advancements in smart materials, nanotechnology, and sustainable manufacturing, new materials are poised to address critical challenges and unlock unprecedented opportunities across industries. As research progresses, addressing challenges such as cost, scalability, and environmental will be essential to fully realize the potential of these groundbreaking materials.