UV resistant

Easy to mix and apply

Low-odor and zero-VOC

High gloss & durable

Low viscosity

Fast-drying Epoxy Resin&Hardener

Vacuum Infusion

Epoxy Resin

Vacuum infusion is a process used in manufacturing to create high-quality composite materials. It involves using a vacuum pump to remove air from a resin and fiberglass cloth or carbon fiber weave, allowing the resin to penetrate each fiber and bond them together for maximum strength and durability. This process involves laying out the carbon fiber in a mold, sealing it with a permeable fabric, and placing it inside a bag. A vacuum pump is then used to draw out the air, allowing the resin and hardener to flow into the mold. Finally, the mold is cured under controlled conditions to create a strong, durable finished product. This precise and efficient process creates high-quality composite materials with excellent strength-to-weight ratios.

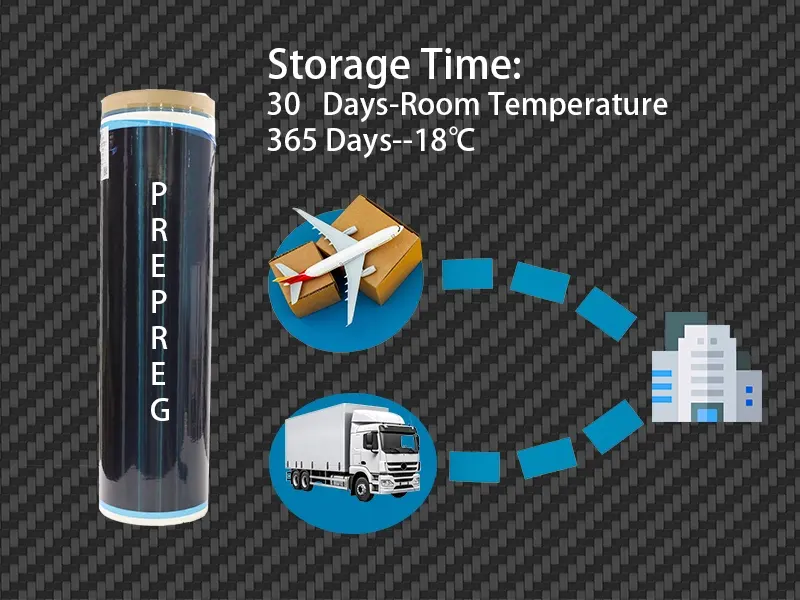

Prepreg-special Resin