Advantages

-

High Strength

Carbon preimpregnated cloth has high tensile strength and stiffness, making it a popular material for aerospace and automotive industry applications.

-

Lightweight

Carbon preimpregnated cloth is extremely lightweight, which is desirable in weight-sensitive applications, such as aircraft and space vehicles.

-

Durability

The material is chemically stable, corrosion-resistant, and has excellent temperature resistance, making it last longer than other materials.

-

Excellent Conductivity

Carbon preimpregnated cloth is an excellent conductor of electricity and heat, making it ideal for applications that require high levels of conductivity.

-

Customizable

Carbon preimpregnated cloth can be customized easily by changing the weave patterns and strand placement to match specific project requirements.

-

Good Dimensional Stability

Due to its high-tensile strength, carbon preimpregnated cloth has good dimensional stability, meaning it deforms very little when subjected to external loads.

Lightweight and Strong

High Resistance to Fatigue

No Tangled Threads

No Color Difference

Stable Pattern

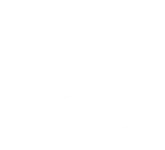

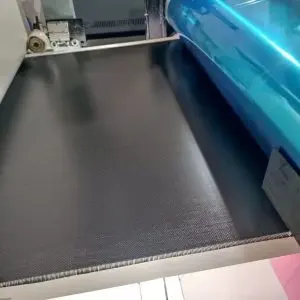

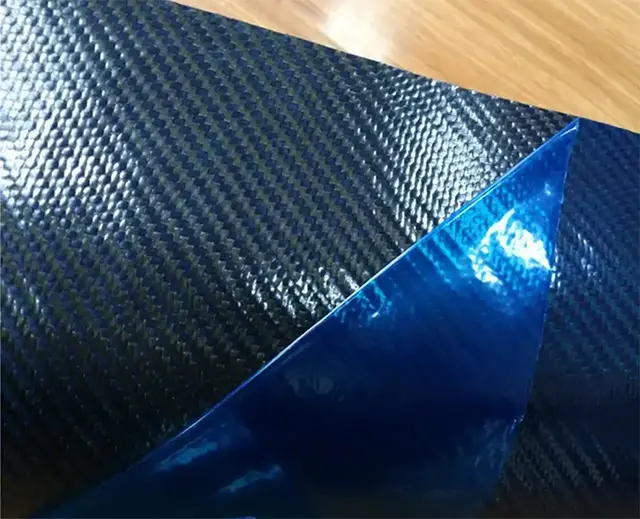

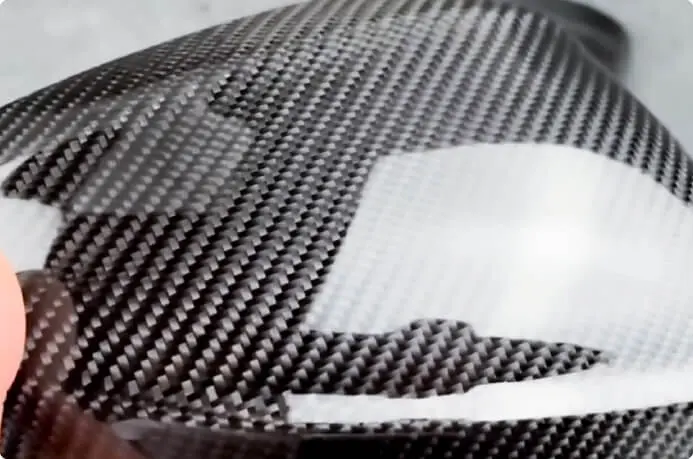

Take a Closer Look of Carbon Fiber Prepreg

Innovative

Excellent Performance

Composed of carbon fibers pre-impregnated with a resin matrix, the pre-preg material offers outstanding mechanical properties and excellent fatigue resistance. The material's lightweight and high strength make it a perfect choice for creating durable and functional devices.

Aerospace

Ideal Materials and Options

Carbon fiber prepreg is commonly used in the aerospace industry to produce aircraft components such as wings, fuselage, and tail sections. Using this lightweight material in aircraft parts increases fuel efficiency and reduces the overall weight of the aircraft.

Versatility in Application

-

Carbon Fiber Car Interior

-

Carbon Fiber Car Interior

-

Carbon Fiber Car Interior

-

Carbon Fiber Car Interior

-

Carbon Fiber Car Interior

-

Carbon Fiber Car Interior

Application Scenario

Industrial Applications

Pre-preg carbon fiber is used in the construction of high-performance industrial components such as wind turbine blades, oil rig platforms, and pressure vessels due to its high strength and resistance to corrosion.

Sports Equipment

High-end car manufacturers use pre-preg carbon fiber to make body panels, aerodynamic components, and suspension systems to reduce the overall weight of the vehicle and improve fuel efficiency.

Automotive

High-end car manufacturers use pre-preg carbon fiber to make body panels, aerodynamic components, and suspension systems to reduce the overall weight of the vehicle and improve fuel efficiency.

Aerospace

Pre-preg carbon fiber is used in the design and construction of aircraft, spacecraft, and satellites due to its lightweight and high-strength properties.