CNC Cutting

CNC cutting of carbon fiber mold is a highly precise method of shaping carbon fiber material into the desired shape and size. CNC, which stands for computer numerical control, allows for the creation of extremely accurate cuts and shapes through the use of computer software programs. With CNC cutting, a block of material, usually metal or plastic, is loaded into the machine, and the computer program sends commands to the cutting tool to produce the desired shape. The cutting tool moves along three axes, X, Y, and Z, to create the mold design. The level of precision achieved with CNC cutting is unmatched compared to traditional methods, resulting in highly accurate molds with smooth surfaces.

Compression Molding

One of the methods used to create carbon fiber products is compression molding. It is a process that involves compressing a composite material, such as carbon fiber, into a mold under high pressure and temperature. It also has a lower environmental compared to other traditional manufacturing methods, as it uses less energy and generates less waste.

Injection Molding

Injection molding of carbon fiber is the process of creating complex, lightweight, and strong parts using carbon fiber reinforced polymer (CFRP) materials. Carbon fiber injection molding involves melting thermoplastic resins and blending them with carbon fiber in a mold, where they are then injected with high-pressure machinery to create the desired shape.

Versatility in Application

-

Carbon Fibers Fins

-

Carbon Fiber Car Interior

-

Pickleball Racket

-

Carbon Fiber Drone

-

Carbon Fiber Helmet

-

Tennis Paddle

Application Scenario

Carbon Fiber Auto Part

Carbon fiber auto parts are the epitome of modern engineering and technology. They are lightweight, strong, and durable. Carbon fiber materials are made through a process where carbon strands are twisted together and bound with a resin to create incredibly strong but light components. In the automotive industry, carbon fiber is a popular choice for sports cars, high-performance vehicles and even luxury cars. These parts are commonly used in the production of hoods, spoilers, mirrors, and even entire body kits.

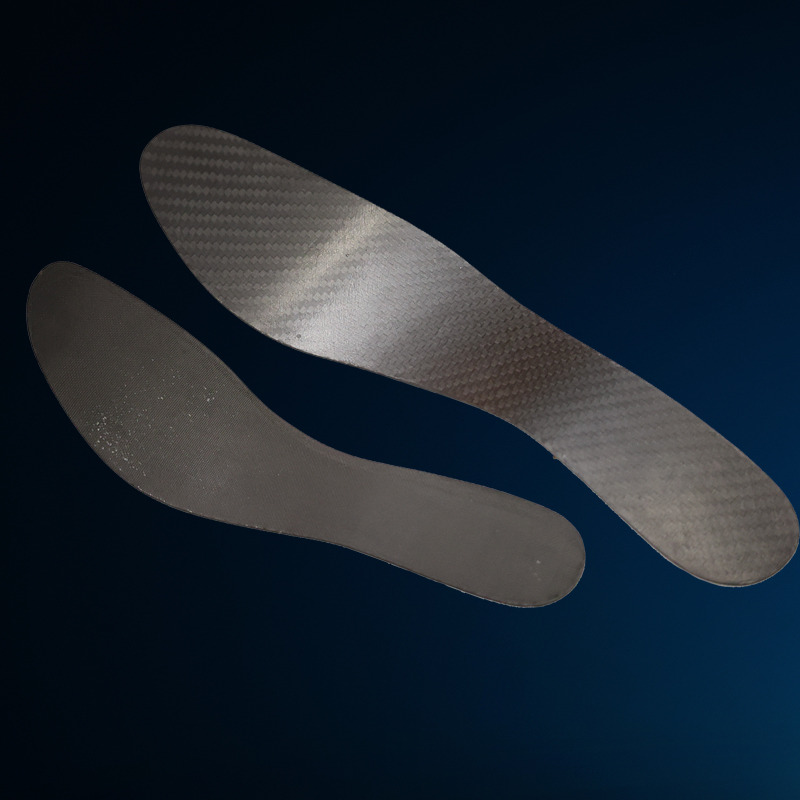

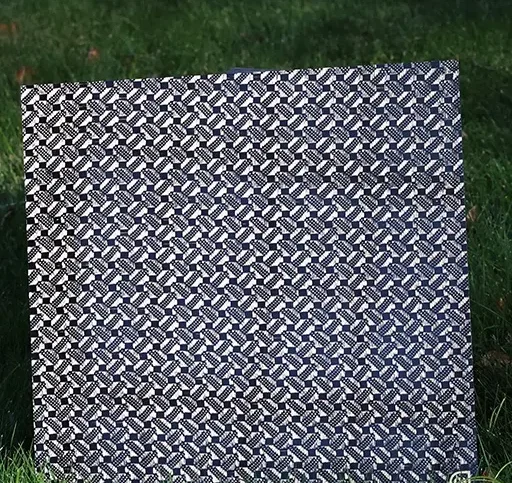

Application Scenario Carbon Fiber Sheet

Carbon fiber sheet is a leading-edge composite material that offers impressive strength, durability, and lightweight properties. Made using carbon fibers, woven into a tough matrix, these sheets offer an exceptional combination of high stiffness, low weight, and excellent heat resistance. Known for their applications across several industries from aerospace, sports, and automotive engineering, carbon fiber sheets have become the material of choice for high-performance applications that require a perfect balance of strength, durability, and lightweight.

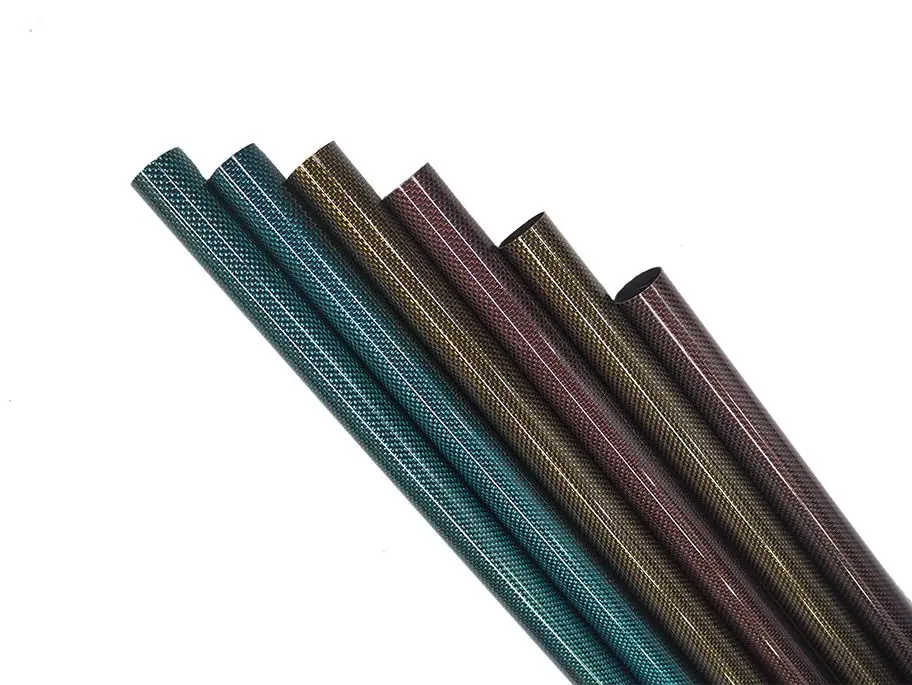

Carbon Fiber Tube

Carbon fiber tubes are increasingly used in various industries, including aerospace, automotive, and sports. Their high strength-to-weight ratio and excellent stiffness make them a popular choice for applications where weight reduction and rigidity are critical. These tubes are made by weaving together thousands of carbon fibers, which are then placed in a mold and bonded with resin. The result is a lightweight, durable, and strong product that has revolutionized many fields.