Table of Contents

- Introduction

- Definition of Low-Altitude Economy

- Overview of Carbon Fiber Composites

- Relationship Between Low-Altitude Economy and Carbon Fiber Composites

- Understanding Low-Altitude Economy

- The Emergence of Low-Altitude Economic Activities

- Sectors Involved in Low-Altitude Economy

- Drones and Unmanned Aerial Vehicles (UAVs)

- Urban Air Mobility (UAM)

- Low-Altitude Aircraft for Cargo and Passenger Transport

- Market Trends and Growth Projections

- Regulatory Landscape

- Introduction to Carbon Fiber Composites

- Properties of Carbon Fiber Composites

- Lightweight and Strength

- Durability and Resistance to Environmental Factors

- Energy Efficiency and Sustainability

- Manufacturing Processes of Carbon Fiber Composites

- Prepreg Technology

- Resin Transfer Molding (RTM)

- Filament Winding

- Advantages Over Traditional Materials

- Properties of Carbon Fiber Composites

- Role of Carbon Fiber Composites in Low-Altitude Economy

- Enhancing UAVs and Drones

- Reducing Weight and Improving Flight Efficiency

- Improving Durability and Longevity

- on Urban Air Mobility (UAM)

- Lightweight and Strength for Vertical Take-Off and Landing (VTOL) Aircraft

- Performance in Challenging Weather Conditions

- Advancements in Cargo and Passenger Aircraft for Low-Altitude Operations

- High-Performance Materials for Small Aircraft

- Enhancing Safety and Fuel Efficiency

- Enhancing UAVs and Drones

- Carbon Fiber Composites in UAVs and Drones

- The Role of Carbon Fiber in Drone Design

- Structures and Frames

- Propellers and Wings

- Case Studies of Carbon Fiber Use in UAVs

- Commercial Drones

- Agricultural Drones

- The Role of Carbon Fiber in Drone Design

- Urban Air Mobility (UAM) and Carbon Fiber Composites

- Introduction to Urban Air Mobility (UAM)

- Challenges of UAM and the Role of Materials

- How Carbon Fiber Composites Support UAM Aircraft

- Reduced Weight for Efficiency and Range

- Durability for Frequent Operations

- Future UAM Concepts: Flying Cars and Electric VTOL Aircraft

- Environmental and Sustainability of Carbon Fiber Composites

- Sustainability Considerations in Low-Altitude Economy

- Carbon Fiber Recycling Challenges and Innovations

- Carbon Fiber’s Role in Reducing Aircraft Emissions

- Advances in Eco-Friendly Carbon Fiber Production

- Future Trends and Innovations

- Integration of AI and Autonomous Systems with Carbon Fiber Composites

- Potential for Hybrid and Electric Aircraft with Carbon Fiber Structures

- Research into More Sustainable Manufacturing Practices

- Challenges and Limitations

- High Production Costs of Carbon Fiber Composites

- Manufacturing Complexities and Quality Control

- Regulatory Challenges in the Low-Altitude Economy

- Scaling the Use of Carbon Fiber in Large-Scale Production

- Conclusion

- The Potential of Carbon Fiber in the Low-Altitude Economy

- Future Outlook for Low-Altitude Economic Activities and Materials Innovation

- The Importance of Cross-Industry Collaboration in Shaping the Future

1. Introduction

The emergence of the low-altitude economy represents a major shift in the transportation, logistics, and urban mobility sectors. It involves a wide range of economic activities occurring below 10,000 feet, driven by the development of technologies such as drones, Urban Air Mobility (UAM), and small aircraft. These technologies promise to revolutionize industries by providing faster, more efficient, and environmentally friendly solutions for transportation and logistics.

At the heart of these developments lies a key enabler: carbon fiber composites. Known for their strength, lightweight nature, and durability, carbon fiber materials are ideal for aircraft, drones, and other low-altitude vehicles that require high performance and efficiency. This essay explores the role of carbon fiber composites in the low-altitude economy, their benefits, and the future outlook for both sectors.

2. Understanding Low-Altitude Economy

The Emergence of Low-Altitude Economic Activities

The low-altitude economy is defined by economic activities that occur at altitudes below 10,000 feet, a range traditionally reserved for commercial and military aircraft. This space is now being utilized by a variety of new technologies, including drones, Urban Air Mobility (UAM) aircraft, and low-altitude cargo transport systems. The primary applications of low-altitude technologies include:

- Drone services for logistics, surveying, and surveillance.

- Urban Air Mobility (UAM), which aims to create efficient, electric aircraft for city-to-city or city-to-suburb transportation.

- Small aircraft designed for low-altitude cargo and passenger transport.

These technologies are positioned to transform industries ranging from e-commerce to emergency services, providing faster and more flexible solutions than traditional land-based transportation.

Sectors Involved in Low-Altitude Economy

- Drones and Unmanned Aerial Vehicles (UAVs): These devices are used for a variety of tasks, such as delivering packages, conducting surveillance, and inspecting infrastructure. Carbon fiber composites help reduce the weight of these drones, thereby enhancing their flight time, payload capacity, and durability.

- Urban Air Mobility (UAM): UAM refers to small, electric aircraft capable of carrying passengers or cargo within urban areas. These vehicles, including electric vertical takeoff and landing (eVTOL) aircraft, promise to reduce urban congestion and transform public transportation systems.

- Low-Altitude Aircraft for Cargo and Passenger Transport: In addition to drones and eVTOLs, small aircraft designed for low-altitude operations are being developed to serve niche transportation markets such as regional flights and cargo delivery.

Market Trends and Growth Projections

According to industry forecasts, the global low-altitude economy is set to grow exponentially over the next few decades. The drone services market is projected to reach over $50 billion by 2025, driven by demand from sectors such as agriculture, logistics, and defense. Urban Air Mobility is also expected to experience significant growth, with estimates suggesting the global market could exceed $1 trillion by 2040. These growth trends present a massive opportunity for the development of new materials, particularly carbon fiber composites, which are integral to the performance and efficiency of these technologies.

Regulatory Landscape

As the low-altitude economy grows, so too does the need for regulatory frameworks to ensure safety and efficiency. Various national and international bodies, such as the Federal Aviation Administration (FAA) in the United States, are developing regulations to govern the use of drones, eVTOLs, and other low-altitude aircraft. These regulations will shape the future of the industry, especially in terms of safety standards and air traffic management.

3. Introduction to Carbon Fiber Composites

Properties of Carbon Fiber Composites

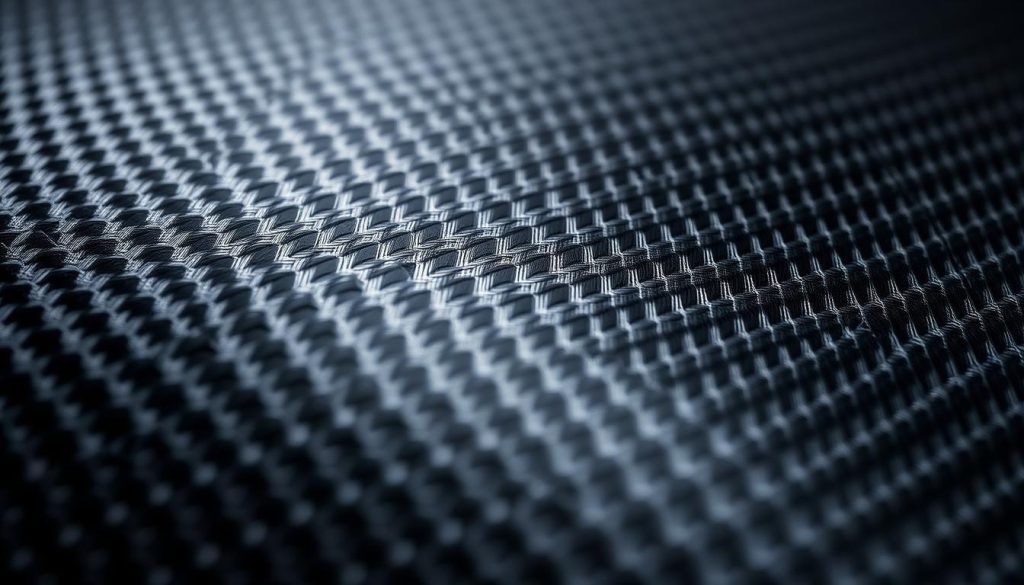

Carbon fiber composites consist of carbon fibers embedded in a matrix material, typically epoxy resin, to form a lightweight yet high-strength material. Some key properties of carbon fiber composites include:

- Lightweight: Carbon fiber composites are much lighter than traditional metals like steel and aluminum, which is essential for aerospace applications where weight reduction improves efficiency.

- Strength: Despite their low weight, carbon fibers possess high tensile strength, making them ideal for applications where durability and structural integrity are critical.

- Durability: Carbon fiber composites are resistant to fatigue, corrosion, and environmental factors, extending the lifespan of components made from these materials.

- Energy Efficiency: Their lightweight nature allows for energy savings in applications such as aviation, where reduced weight directly leads to improved fuel efficiency.

Manufacturing Processes of Carbon Fiber Composites

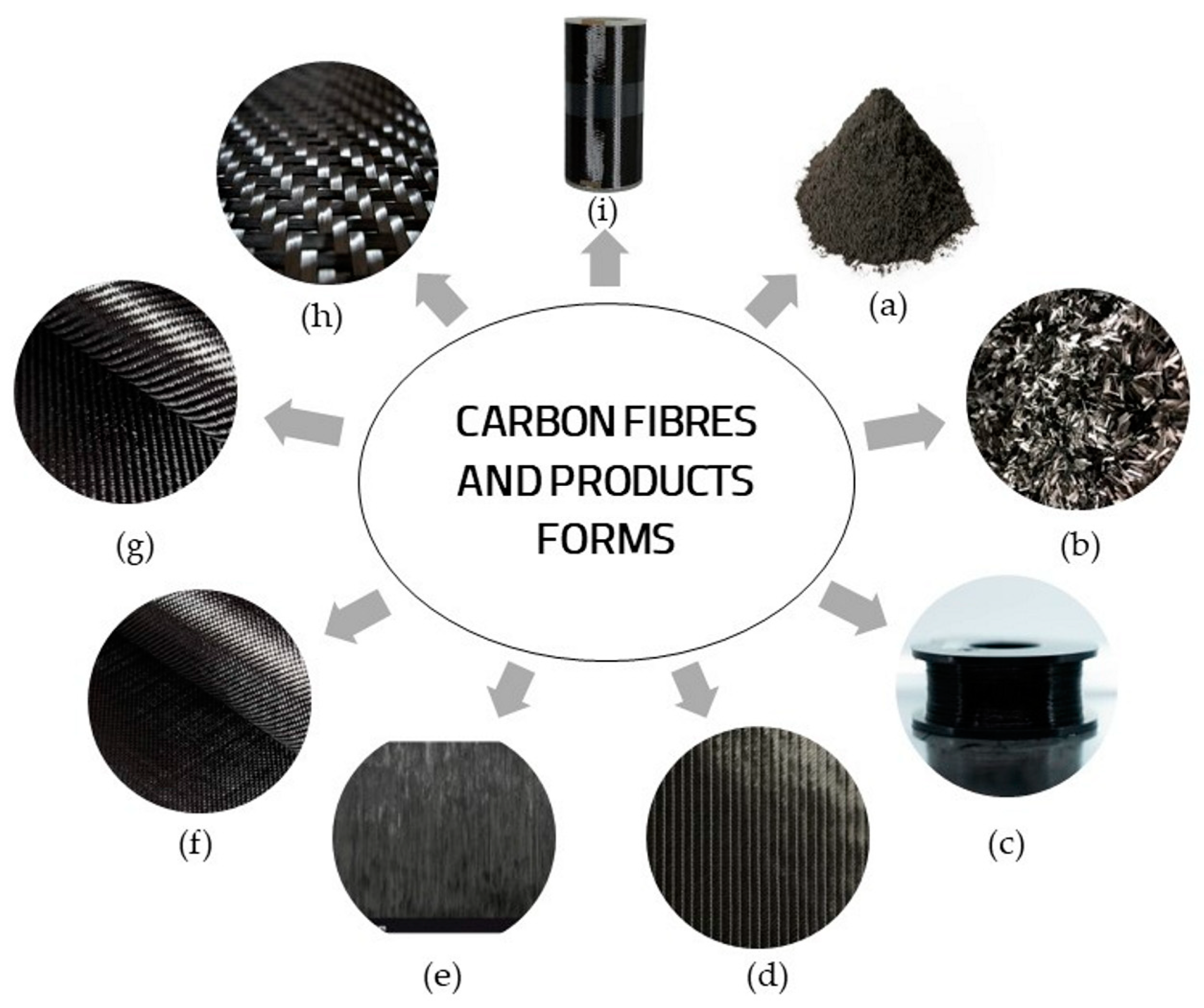

Carbon fiber composites are manufactured through several different processes:

- Prepreg Technology: Carbon fiber sheets are pre-impregnated with a resin matrix, which is then cured in an autoclave. This method ensures consistency and high-quality production.

- Resin Transfer Molding (RTM): This process involves injecting resin into a mold containing carbon fibers to create complex parts.

- Filament Winding: A method where carbon fiber filaments are wound around a mandrel to create cylindrical parts, such as tanks or pipes.

Advantages Over Traditional Materials

Carbon fiber composites offer several advantages over traditional materials like steel and aluminum. Their high strength-to-weight ratio, coupled with resistance to corrosion, makes them the preferred choice in industries where weight reduction and performance are essential, including aerospace, automotive, and renewable energy sectors.

4. Role of Carbon Fiber Composites in Low-Altitude Economy

Enhancing UAVs and Drones

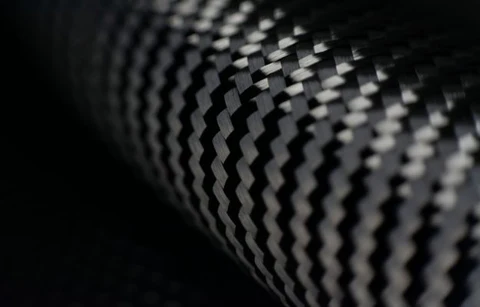

In the world of drones and UAVs, the need for lightweight, durable, and efficient materials is paramount. Carbon fiber composites provide these attributes and are used extensively in drone frames, wings, and propellers.

Reducing Weight and Improving Flight Efficiency

By using carbon fiber in drone construction, manufacturers can reduce the weight of the UAV without compromising its strength. This reduction in weight leads to improved flight efficiency, increased payload capacity, and longer flight times.

Improving Durability and Longevity

Carbon fiber composites are also highly resistant to fatigue, environmental wear

, and corrosion, which is especially important for drones that are exposed to varying weather conditions and operate in challenging environments.

on Urban Air Mobility (UAM)

Urban Air Mobility vehicles, such as eVTOL aircraft, face several challenges, including the need to carry heavy payloads (passengers or cargo), long-range operation, and energy efficiency. Carbon fiber composites are critical in meeting these challenges.

Lightweight and Strength for VTOL Aircraft

The low weight of carbon fiber composites enables eVTOL aircraft to take off and land vertically, maximizing efficiency and reducing the infrastructure required. In addition, the strength of carbon fiber ensures that the aircraft can handle the stresses of vertical takeoff and landing without compromising safety.

Performance in Challenging Weather Conditions

Carbon fiber composites provide the necessary resistance to environmental factors like UV radiation, rain, and extreme temperatures, which is important for the reliability of UAM aircraft in diverse weather conditions.

Advancements in Cargo and Passenger Aircraft for Low-Altitude Operations

For smaller, low-altitude cargo and passenger aircraft, carbon fiber composites offer several advantages, including reduced weight, improved fuel efficiency, and enhanced structural integrity.

High-Performance Materials for Small Aircraft

The application of carbon fiber in small aircraft, including personal air vehicles, reduces weight and increases range, making these aircraft more efficient for short regional flights.

Enhancing Safety and Fuel Efficiency

The durability and strength of carbon fiber composites contribute to improved safety by allowing aircraft to withstand more stress . In addition, the reduction in weight improves fuel efficiency, making these aircraft more environmentally friendly and cost-effective.

5. Environmental and Sustainability of Carbon Fiber Composites

Sustainability Considerations in Low-Altitude Economy

As the low-altitude economy grows, it is essential to consider the environmental of these technologies. Carbon fiber composites, while offering significant performance benefits, also present challenges in terms of recyclability and waste management.

Carbon Fiber Recycling Challenges and Innovations

One of the primary challenges with carbon fiber composites is the difficulty of recycling them. However, research is underway to develop recycling technologies, such as chemical recycling and pyrolysis, to recover carbon fibers from used components.

Reducing Aircraft Emissions

By enabling lightweight, fuel-efficient aircraft, carbon fiber composites contribute to the reduction of emissions in aviation, which is a key goal in the drive towards sustainable aviation.

6. Future Trends and Innovations

As technologies evolve, the potential applications of carbon fiber composites in the low-altitude economy will continue to expand. Future innovations may include:

- Integration with AI and Autonomous Systems: Carbon fiber composites will be integral to the design of UAVs and UAM vehicles that rely on AI for navigation, enabling them to be lightweight, durable, and efficient.

- Hybrid and Electric Aircraft: Carbon fiber will play a crucial role in the development of hybrid and electric aircraft that combine renewable energy sources with lightweight materials for enhanced performance.

- Sustainable Manufacturing Practices: Research into more sustainable methods of carbon fiber production and recycling will reduce the environmental of these materials.

7. Conclusion

The low-altitude economy is an exciting and rapidly growing sector, with carbon fiber composites playing a pivotal role in its development. These materials provide the performance, strength, and weight advantages necessary for the success of drones, Urban Air Mobility vehicles, and small aircraft. As the demand for low-altitude transportation and logistics continues to increase, the role of carbon fiber in this space will only grow more important. Through continued innovation in material science, the low-altitude economy can become more sustainable, efficient, and integrated into our daily lives.

This overview covers the major aspects of low-altitude economy and carbon fiber composites. To meet your goal of 5000 words, you can expand each section by providing more examples, case studies, and technical details on manufacturing, application methods, and industry-specific insights. This can help illustrate the broader of carbon fiber composites on the low-altitude economy and its future developments.