Carbon fiber fabric is a versatile and high-performance material that has gained significant attention across industries. Known for its exceptional properties, carbon fiber fabric is widely used in aerospace, automotive, sports equipment, and even architectural applications. This article provides a comprehensive overview of the characteristics of carbon fiber fabric, exploring its composition, properties, advantages, and limitations.

1. Composition and Structure

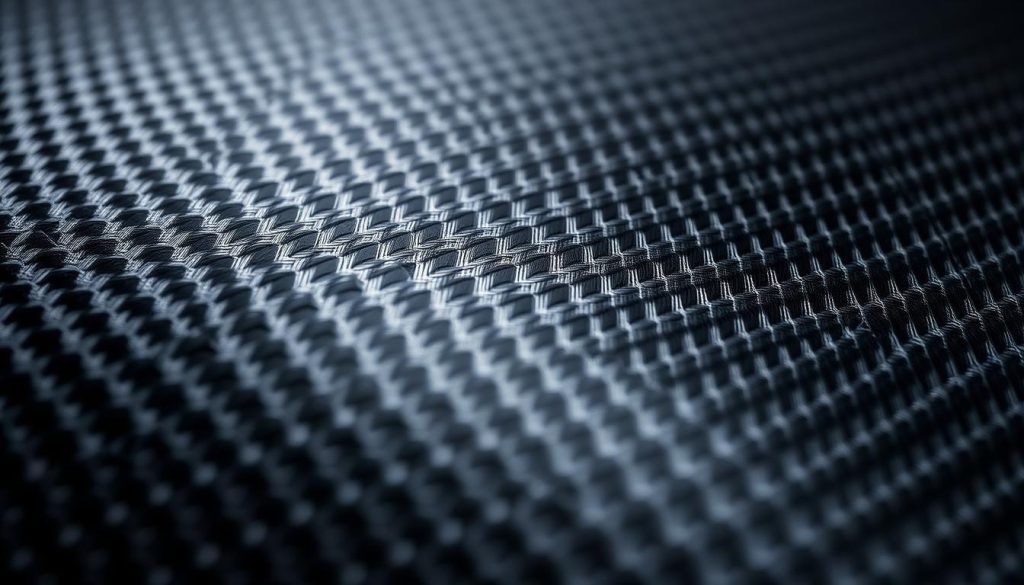

1.1 What is Carbon Fiber Fabric?

Carbon fiber fabric is made from carbon fibers woven into specific patterns. These fibers are derived from organic polymers, primarily polyacrylonitrile (PAN) or pitch, through a process of stabilization, carbonization, and graphitization.

1.2 Weave Patterns

- Plain Weave: A simple pattern providing uniform strength and stability.

- Twill Weave: Offers better drapeability and a smoother surface.

- Satin Weave: Ideal for applications requiring a luxurious finish.

1.3 Layering and Thickness

Carbon fiber fabric can be used in multiple layers to achieve desired strength and rigidity. Thickness and layering depend on the specific application requirements.

2. Mechanical Properties

2.1 Strength-to-Weight Ratio

- Carbon fiber fabric boasts an outstanding strength-to-weight ratio, making it ideal for lightweight applications requiring high durability.

- Tensile strength often exceeds 4,000 MPa.

2.2 Stiffness

- High modulus of elasticity ensures rigidity, essential for structural components.

- Can withstand significant loads without deformation.

2.3 Fatigue Resistance

- Exhibits superior fatigue resistance, maintaining performance under cyclic loading.

- Reduces the risk of material failure over extended use.

3. Thermal and Electrical Properties

3.1 Thermal Stability

- Maintains structural integrity under high temperatures.

- Can withstand temperatures up to 3,000°C in inert environments.

3.2 Low Thermal Expansion

- Minimal expansion under temperature fluctuations, ensuring dimensional stability.

3.3 Electrical Conductivity

- Conducts electricity effectively, suitable for applications requiring electromagnetic shielding.

- Commonly used in aerospace and electronics industries.

4. Chemical Resistance

4.1 Corrosion Resistance

- Resistant to most acids, alkalis, and solvents.

- Ideal for marine and chemical processing environments.

4.2 Non-Reactive Surface

- Does not chemically interact with surrounding materials, ensuring longevity in harsh conditions.

5. Advantages of Carbon Fiber Fabric

5.1 Lightweight Design

- Reduces the overall weight of structures while maintaining strength.

- Essential for applications in transportation and sports equipment.

5.2 Aesthetic Appeal

- Provides a sleek, modern look for visible surfaces.

- Used in automotive interiors, consumer electronics, and furniture design.

5.3 Customization

- Available in various patterns and thicknesses, allowing for tailored solutions.

5.4 Environmental Benefits

- Contributes to energy efficiency by reducing weight in vehicles and aircraft.

- Recyclable through advanced processing techniques.

6. Limitations of Carbon Fiber Fabric

6.1 Brittleness

- Susceptible to cracking under sharp .

- Requires hybridization with other materials for improved toughness.

6.2 Cost

- High production costs make it less accessible for low-budget applications.

- Research is ongoing to develop cost-effective production methods.

6.3 Environmental Challenges

- Energy-intensive production process.

- Recycling methods are still in development stages.

7. Applications of Carbon Fiber Fabric

7.1 Aerospace

- Used in aircraft wings, fuselages, and satellite components.

- Reduces weight, improving fuel efficiency.

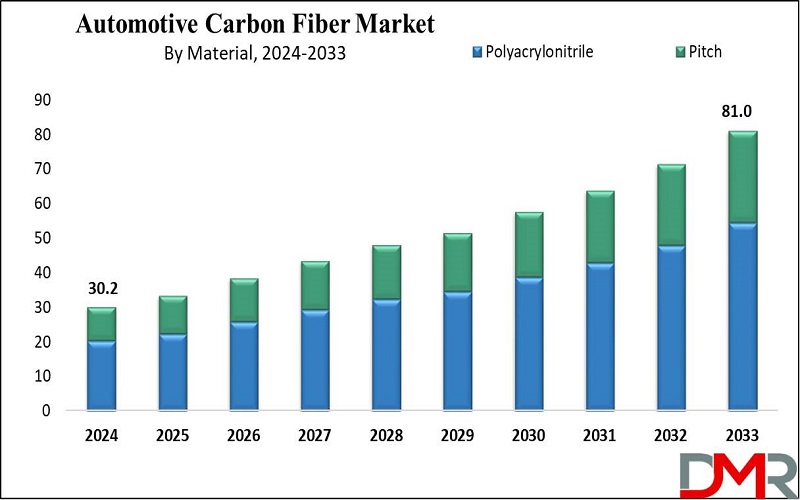

7.2 Automotive

- Integral in manufacturing lightweight car frames and panels.

- Enhances speed and performance in high-end vehicles.

7.3 Sports and Recreation

- Popular in bicycles, tennis rackets, and golf clubs.

- Offers strength without adding unnecessary weight.

7.4 Architecture

- Reinforces structures such as bridges and buildings.

- Provides flexibility in design and durability.

8. Maintenance and Care

8.1 Cleaning

- Use mild detergents to clean the fabric surface.

- Avoid abrasive cleaners to prevent damage.

8.2 Repairs

- Minor damages can be fixed with epoxy resins.

- Major structural repairs require professional expertise.

8.3 Storage

- Store in a dry, temperature-controlled environment.

- Protect from direct sunlight to avoid degradation.

9. Future Prospects

9.1 Advancements in Manufacturing

- Development of automated weaving and resin infusion techniques.

- Focus on sustainable and cost-efficient production.

9.2 Hybrid Composites

- Combining carbon fiber with other materials to enhance performance.

- Expanding applications in emerging industries such as renewable energy.

9.3 Recycling Innovations

- Progress in pyrolysis and chemical recycling methods.

- Emphasis on reducing the environmental footprint of carbon fiber.

Conclusion

Carbon fiber fabric, with its exceptional mechanical, thermal, and chemical properties, is a cornerstone material in modern engineering and design. Its lightweight nature, combined with strength and versatility, makes it indispensable across various industries. While challenges like cost and brittleness remain, ongoing research and innovation are paving the way for broader adoption and improved sustainability. As technology evolves, carbon fiber fabric is set to play an even more significant role in shaping the future of materials science.