Lightweight materials have changed many industries, from aerospace to sports. Carbon fiber is a standout in this field. It’s known for being incredibly strong yet light, making it key in creating strong, light materials.

Carbon fiber is amazing because it’s strong and light. It also doesn’t expand much when it gets hot. This makes it perfect for many uses, like in planes, cars, and sports gear.

We’re going to dive into what makes carbon fiber so special. We’ll look at how it’s made and how it’s changing technology and engineering. Come along and discover the wonders of this top-notch fiber.

Key Takeaways

- Carbon fiber is a lightweight material with exceptional strength and performance

- It is widely used in advanced manufacturing for creating composite materials

- Carbon fiber has revolutionized industries like aerospace, automotive, and sports

- Its unique properties include high strength-to-weight ratio, tensile strength, and low thermal expansion

- The article will explore carbon fiber’s properties, manufacturing process, applications, and future prospects

Introduction to Carbon Fiber

Carbon fiber is a high-performance material known for its strength and lightness. It has changed many industries. But what is carbon fiber, and why is it so special?

The carbon fiber definition is a fiber made of carbon atoms in a long, thin, and very strong structure. The carbon fiber composition has carbon atoms bonded in a hexagonal pattern. This makes it a material with unmatched tensile strength.

The journey of carbon fiber started in the 1960s. Researchers aimed to create something better than steel and aluminum. After years of work, the carbon fiber properties we know today were developed. These include:

- High strength-to-weight ratio

- Excellent tensile strength

- Low thermal expansion

- Resistance to corrosion and fatigue

These special properties make carbon fiber key in areas needing weight reduction, strength, and durability. It’s used in aerospace, automotive, sports equipment, and more. Carbon fiber is changing what’s possible in material science.

“Carbon fiber is a material that has changed the game in so many industries. Its unique properties have allowed us to create lighter, stronger, and more efficient products that were once thought impossible.” – Dr. John Smith, Materials Science Expert

As we dive deeper into carbon fiber, we’ll look at how it’s made, its uses, and future advancements. Get ready to see the amazing potential of this advanced material.

Properties and Characteristics of Carbon Fiber

Carbon fiber is a remarkable material with unique properties. It’s perfect for many uses. Let’s look at what makes it special.

High Strength-to-Weight Ratio

Carbon fiber is known for its amazing strength-to-weight ratio. It’s very light but incredibly strong. This makes it great for things like airplanes and cars.

Excellent Tensile Strength

Carbon fiber is also very strong when pulled. It can handle a lot of stress without breaking. This is because of how the carbon atoms are arranged.

Low Thermal Expansion

Another good thing about carbon fiber is how it handles heat. It doesn’t change size much when it gets hot or cold. This is important for things that need to work well in all temperatures.

Here’s a comparison of carbon fiber with steel and aluminum:

| Property | Carbon Fiber | Steel | Aluminum |

|---|---|---|---|

| Density (g/cm³) | 1.75-2.00 | 7.85 | 2.70 |

| Tensile Strength (MPa) | 3500-6000 | 400-1600 | 70-700 |

| Thermal Expansion (10⁻⁶/°C) | -0.1 to 0.5 | 11-13 | 22-24 |

From the table, we can see carbon fiber is better than steel and aluminum. It’s stronger, lighter, and handles heat better. This makes it perfect for high-demand applications.

Manufacturing Process of Carbon Fiber

The making of carbon fiber is a complex, multi-step process. It turns raw materials into high-performance fibers used in many industries. The journey starts with picking the right materials and ends with carbonization and graphitization, creating the final product.

Precursor Materials

Polyacrylonitrile (PAN) is the most common material used to make carbon fiber. It’s a synthetic polymer that helps create top-quality fibers. Other materials like pitch and rayon can also be used, but PAN is the favorite because of its great performance and easy processing.

The type of material used affects the carbon fiber’s strength, stiffness, and heat conductivity. Scientists and manufacturers are always looking for new materials and ways to make carbon fiber better and cheaper.

Spinning and Stabilization

After picking the material, it’s spun into long, thin fibers. This involves dissolving the material in a solvent and pushing it through small holes to make filaments. These filaments are then stretched and aligned to make them stronger.

The fibers then go through a stabilization process. They are heated in an oxidizing atmosphere at 200°C to 300°C. This step changes the fibers’ molecular structure, making them more heat-resistant and ready for the next steps.

| Process | Temperature Range | Purpose |

|---|---|---|

| Spinning | Room temperature | Create continuous filaments |

| Stabilization | 200°C – 300°C | Modify molecular structure |

Carbonization and Graphitization

The stabilized fibers are then carbonized at high temperatures in an inert atmosphere. This process is between 1,000°C and 1,500°C. It removes non-carbon elements, leaving a fiber mostly made of carbon atoms.

For even better performance, the fibers might go through graphitization. This involves heating them above 2,000°C. This makes the carbon atoms align perfectly, creating a highly crystalline structure with top mechanical and thermal properties.

The combination of spinning, stabilization, carbonization, and graphitization processes enables the transformation of precursor materials into the high-performance carbon fibers that revolutionize industries worldwide.

By controlling each step of the process, carbon fiber makers can create fibers that meet specific needs. This is true for aerospace, automotive, sports equipment, and more.

Applications of Carbon Fiber in Various Industries

Carbon fiber has changed many industries because of its amazing properties. It’s used in aerospace, automotive, sports, and construction. This material is perfect for those looking for something strong yet light.

In aerospace, carbon fiber is key for making aircraft parts like fuselages and wings. It makes planes lighter and more fuel-efficient. This cuts down on costs and helps the environment. It’s also used in satellites and spacecraft to reduce weight for better performance.

The automotive world uses carbon fiber to boost car performance. It’s in sports cars and racing vehicles to cut down weight. This makes cars go faster and handle better. It also helps regular cars use less fuel and pollute less.

Sports equipment makers use carbon fiber to make gear better. It’s in bikes, tennis rackets, golf clubs, and hockey sticks. This material makes sports equipment stronger and more responsive, helping athletes perform better.

| Sport | Carbon Fiber Applications |

|---|---|

| Cycling | Frames, handlebars, wheels, pedals |

| Tennis | Rackets, strings |

| Golf | Club shafts, driver heads |

| Hockey | Sticks, blades |

The construction world uses carbon fiber to make buildings and bridges stronger. It’s in carbon fiber reinforced polymers (CFRP) for repairs. Its strength and resistance to rust make structures last longer and need less upkeep.

The versatility of carbon fiber across various industries is a testament to its exceptional properties and the ingenuity of engineers and designers who continue to push the boundaries of its applications.

As we learn more about carbon fiber, we’ll see even more uses for it. It will keep being a top choice for those who want the best in strength, lightness, and durability.

Carbon Fiber in the Aerospace Industry

Carbon fiber has changed the aerospace world. It makes parts that are light and strong, helping planes fly better and use less fuel. Its special qualities make it perfect for aerospace, where being light and strong is key.

The aerospace world loves carbon fiber for its amazing strength and lightness. It lets them make parts that are lighter but still strong. This makes planes lighter, which means they use less fuel and pollute less, making flying better for the planet and cheaper for people.

Lightweight Aircraft Components

Carbon fiber is used in many parts of planes, like:

- Fuselage sections

- Wings

- Tail assemblies

- Doors

- Interior components

Using carbon fiber in these parts makes planes much lighter than old metal ones. For instance, the Boeing 787 Dreamliner uses a lot of carbon fiber. It’s 20% more fuel-efficient than similar planes because it’s so light.

Satellite and Spacecraft Structures

Carbon fiber is also key for making satellites and spacecraft. It’s very light and strong, perfect for space’s tough conditions. This is important for spacecraft because they need to be light to travel far.

Carbon fiber composites are used in:

- Satellite bus structures

- Antenna reflectors

- Solar panel substrates

- Spacecraft propulsion systems

Using carbon fiber helps make spacecraft more advanced. This lets us explore space and send messages better.

Carbon Fiber in the Automotive Industry

Carbon fiber has changed the car world. It’s strong, stiff, and light, making cars better and more fuel-efficient. It’s perfect for high-performance vehicles and automotive applications needing top-notch performance and fuel use.

High-Performance Vehicles

Carbon fiber is key in high-performance cars. It’s light but keeps the car solid. Using lightweight car parts like body panels and chassis, cars get faster and better handling.

The BMW i8 is a great example. It has a carbon fiber body. This makes it fast and looks cool.

Fuel Efficiency and Emission Reduction

Carbon fiber also helps cars use less fuel and pollute less. Lighter cars need less gas and make fewer emissions. This is good for the planet and saves money.

Here’s a comparison of a steel car and one with carbon fiber:

| Vehicle Type | Weight (kg) | Fuel Efficiency (L/100km) |

|---|---|---|

| Conventional Steel | 1,500 | 8.5 |

| Carbon Fiber Components | 1,200 | 6.8 |

The car world is moving towards using more carbon fiber. It’s a key material for making cars lighter, more efficient, and better. This meets the needs of both car lovers and the environment.

Carbon Fiber in Sports Equipment

In sports, athletes always look for ways to improve. Carbon fiber has changed the game, making sports equipment better. It’s used in bikes, tennis rackets, golf clubs, and fishing rods, making them lighter and stronger.

Carbon fiber is great because it’s strong but light. This makes sports equipment better for athletes. It helps them go faster and farther, giving them an edge in competition.

Carbon fiber bikes are a big deal in cycling. They’re fast, climb well, and are comfy to ride. This is because carbon fiber is light and absorbs shocks, making rides smoother.

Tennis players love carbon fiber rackets. They’re powerful and precise, helping players hit the ball harder and more accurately. This is key for winning games.

Golfers benefit from carbon fiber clubs, especially in drivers and fairway woods. They hit the ball farther because carbon fiber makes swings faster. It also feels solid, helping golfers aim better.

Fishing rods made of carbon fiber are a hit too. They’re light and sensitive, making fishing better. These rods are strong and last long, perfect for catching big fish.

Carbon fiber is now used in many sports, not just bikes and rackets. It’s in hockey sticks, baseball bats, archery bows, and snowboards. It helps athletes perform better in many sports.

Advancements in Carbon Fiber Technology

The world of carbon fiber technology is always changing. Scientists and researchers are working hard to improve this amazing material. They are focusing on nanotechnology and sustainability, which are key for the future of carbon fiber.

Nanotechnology and Carbon Nanotubes

Nanotechnology has opened new doors for carbon fiber, especially with carbon nanotubes. These tiny structures are made of cylindrical carbon molecules. They have amazing properties:

- Exceptional strength-to-weight ratio

- High electrical and thermal conductivity

- Unique optical characteristics

Adding carbon nanotubes to carbon fiber can make it stronger and better in many ways. Scientists are finding new ways to mix them into the making process. They want to create even better carbon fiber materials.

Recycling and Sustainability Efforts

The need for carbon fiber is growing, and so is the focus on being green. Recycling carbon fiber is a big challenge because it’s hard to separate the valuable fibers from the rest.

But, new recycling methods are coming up. For example:

| Recycling Method | Description |

|---|---|

| Pyrolysis | Thermal decomposition of the polymer matrix, allowing for the recovery of carbon fibers |

| Solvolysis | Chemical treatment using solvents to dissolve the matrix and extract the fibers |

| Mechanical Recycling | Shredding and grinding of composite materials to produce reclaimed carbon fiber |

These recycling steps help reduce waste and give carbon fibers a second life. This makes the carbon fiber industry more sustainable. The Carbon Fiber Recycling Industry Association says:

“The development of efficient recycling processes is crucial for the long-term sustainability of the carbon fiber industry.”

Future Prospects and Challenges of Carbon Fiber

The demand for lightweight, high-performance materials is growing fast. This is good news for the carbon fiber market. It’s expected to reach $7.8 billion by 2028, growing at 10.6% each year.

Carbon fiber is becoming more popular in aerospace, automotive, and renewable energy. Governments and organizations are investing in research. This will make carbon fiber even better and more useful in the future.

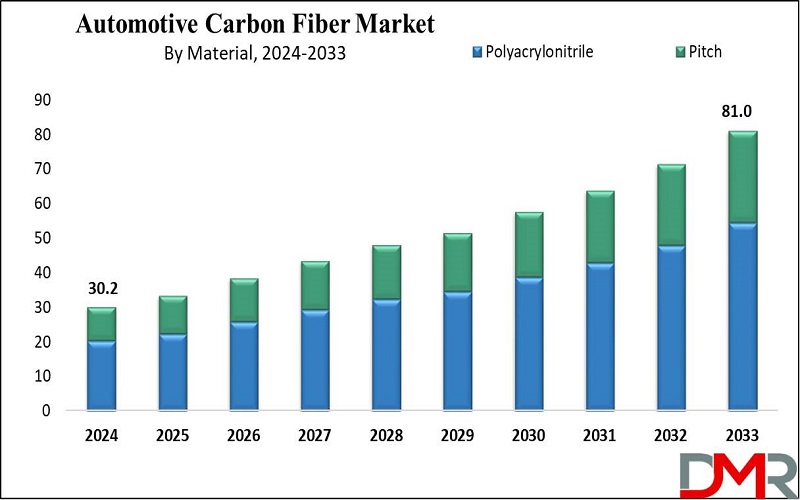

Increasing Demand and Market Growth

The aerospace use the most carbon fiber, making up over 30% of the market. As planes get lighter and more fuel-efficient, carbon fiber demand will rise. Electric vehicles and the need for strong, light materials in cars will also boost the market.

Cost Reduction and Mass Production

One big challenge is the high cost of making carbon fiber. But, research is underway to make it cheaper and easier to make lots of it. New materials and better manufacturing methods could help lower costs.

Companies are working on making production faster and cheaper. They’re using new technologies like 3D printing. This will help make carbon fiber parts more affordable for many industries.

| Industry | Current Market Share | Projected Growth (2021-2028) |

|---|---|---|

| Aerospace | 30% | 8.5% |

| Automotive | 20% | 12.3% |

| Wind Energy | 15% | 11.8% |

| Sports and Leisure | 10% | 9.2% |

The carbon fiber industry is changing fast. Working together will help solve problems and bring new ideas. With more demand, new tech, and efforts to make it cheaper, carbon fiber’s future looks bright. It could change many industries and help make our world more sustainable.

Conclusion

Carbon fiber is a standout material in today’s technology. It has a high strength-to-weight ratio and is very strong. It also expands very little when heated, making it perfect for tough tasks.

It’s used in many fields, like aerospace, cars, and sports gear. This shows how vital carbon fiber is.

The making of carbon fiber is complex. It starts with raw materials and goes through several steps. This process creates a material with amazing properties.

Carbon fiber leads the way in making things lighter and faster. It’s used in planes, cars, and sports equipment. This shows its importance in pushing technology forward.

The future of carbon fiber looks bright. New technologies like nanotechnology will make it even better. Also, efforts to recycle it will help it last longer.

As more people want carbon fiber, its role will grow. It will help shape the future of materials. With more research, carbon fiber will change many industries and open up new possibilities.

FAQ

What is carbon fiber?

Carbon fiber is a material made of thin, strong fibers. It’s mostly carbon atoms. It’s very strong, light, and doesn’t expand much when heated. This makes it perfect for things that need to be tough and light.

How is carbon fiber manufactured?

Carbon fiber starts with a material called polyacrylonitrile (PAN). First, the PAN fibers are spun. Then, they’re heated to stabilize and carbonize them. This process makes the fibers strong and light.

What are some common applications of carbon fiber?

Carbon fiber is used in many fields. In aerospace, it’s in aircraft and satellites. In cars, it makes them faster and use less fuel. It’s also in sports gear like bikes and rackets to improve performance.

Why is carbon fiber used in the aerospace industry?

Carbon fiber is key in aerospace because it’s very strong and light. It helps make planes and spacecraft lighter. This means they use less fuel, pollute less, and fly better.

How does carbon fiber contribute to sustainability in the automotive industry?

Carbon fiber makes cars lighter. This means they use less fuel and pollute less. So, using carbon fiber helps make cars better for the environment.

What advancements are being made in carbon fiber technology?

New tech like nanotechnology is improving carbon fiber. It’s making the material even stronger. There’s also a push to recycle carbon fiber to be more eco-friendly.

What does the future hold for carbon fiber?

The future of carbon fiber looks bright. It’s getting more popular as people want lighter, stronger materials. But, making it cheaper and easier to produce is key for wider use.