As the automotive industry shifts towards sustainable energy, electric vehicles (EVs) are becoming an integral part of the transportation landscape. Along with advancements in battery technology and power management, reducing vehicle weight has emerged as a critical factor in enhancing the range and efficiency of EVs. This need for lightweight materials has positioned carbon fiber composites as a key material in electric vehicle design and manufacturing.

Carbon fiber, known for its exceptional strength-to-weight ratio, durability, and corrosion resistance, offers significant benefits to electric vehicles. From improving battery efficiency to enhancing vehicle performance, carbon fiber is reshaping the future of EVs. In this comprehensive discussion, we will explore the applications of carbon fiber in electric vehicles, the advantages it offers, the challenges associated with its adoption, and the future directions of carbon fiber in the EV industry.

1. Why Lightweight Materials Matter in Electric Vehicles

on Battery Range

The efficiency of an electric vehicle largely depends on its ability to travel longer distances on a single charge. One of the primary constraints for EVs is battery capacity and the associated weight. Batteries are significantly heavy, and any reduction in vehicle weight directly contributes to improved battery efficiency and range. By replacing traditional materials like steel with carbon fiber composites, manufacturers can achieve significant weight reductions, thereby extending the vehicle’s range.

Performance and Efficiency

A lighter vehicle not only extends battery range but also enhances performance, including acceleration, handling, and braking. Reduced weight means less power is required to move the vehicle, improving overall energy efficiency. Carbon fiber, being significantly lighter than metals such as steel and aluminum, offers a unique opportunity to enhance these performance aspects without compromising safety or durability.

Reducing Energy Consumption

Every pound of weight saved translates into reduced energy consumption, which is crucial for electric vehicles aiming to compete with traditional gasoline-powered cars. Carbon fiber’s low density and high strength make it an ideal material to achieve these goals. As a result, the adoption of carbon fiber in various components of electric vehicles can lead to substantial improvements in energy efficiency.

2. Key Applications of Carbon Fiber in Electric Vehicles

Chassis and Body Panels

The chassis and body panels are fundamental structures of a vehicle. Traditional materials like steel, while strong and cost-effective, add considerable weight. Replacing these with carbon fiber composites allows automakers to achieve weight savings of up to 50%. Carbon fiber’s strength ensures that these structures remain rigid and durable while contributing to overall weight reduction.

In EVs, carbon fiber chassis designs enable better handling and stability due to lower center-of-gravity effects, which is especially important for high-performance electric cars. Manufacturers like BMW with the “i3” and “i8” have pioneered the use of carbon fiber reinforced plastics (CFRP) for these applications, setting a trend for other automakers to follow.

Battery Housings

The battery pack is the heaviest component of an electric vehicle. Efficient battery housing structures that provide protection while minimizing weight are essential for EV performance. Carbon fiber composites are increasingly used to create lightweight, strong, and thermally stable battery housings.

Carbon fiber’s ability to withstand high temperatures and resist corrosion makes it an ideal material for battery enclosures, ensuring safety and durability. Furthermore, the weight savings from using carbon fiber for battery housings help offset the mass of the batteries, enhancing vehicle range.

Interior Components

In addition to exterior structures, carbon fiber is being used extensively for interior components in electric vehicles. These include seats, dashboards, door panels, and trim elements. Carbon fiber’s lightweight properties contribute to reducing the overall vehicle weight, while its sleek, high-tech appearance appeals to modern consumers.

Carbon fiber interior components offer durability and design flexibility, allowing manufacturers to create innovative and aesthetically pleasing designs without adding excess weight.

Suspension Systems

Suspension components such as control arms, struts, and springs are critical for maintaining vehicle stability and comfort. Carbon fiber composites are being increasingly used in these systems due to their strength, stiffness, and lightweight characteristics. Lighter suspension components help reduce unsprung mass, improving handling, ride quality, and efficiency.

Wheels and Rims

Carbon fiber wheels offer significant weight reduction compared to traditional aluminum or steel wheels. Lighter wheels improve acceleration, braking, and overall handling. In electric vehicles, where efficiency is paramount, carbon fiber wheels contribute to extended range and better energy conservation.

Additionally, carbon fiber’s strength ensures that wheels remain durable even under high stress, making them a reliable choice for performance-oriented EVs.

Driveshafts and Powertrain Components

Driveshafts made from carbon fiber composites are lighter and stiffer than traditional steel driveshafts. This leads to improved power delivery, reduced rotational mass, and enhanced vehicle dynamics. In electric vehicles, carbon fiber driveshafts contribute to smoother power transmission and better efficiency.

Other powertrain components, such as motor housings and transmission casings, can also benefit from carbon fiber’s lightweight and durable properties, reducing the overall mass of the EV’s drivetrain.

Crash Structures and Safety Components

Safety is a primary concern in vehicle design, and carbon fiber composites offer excellent energy absorption properties during . Carbon fiber crash structures can dissipate energy effectively, providing enhanced protection for passengers. These materials can be designed to crumple strategically during collisions, improving safety while maintaining a lightweight design.

3. Advantages of Using Carbon Fiber in Electric Vehicles

High Strength-to-Weight Ratio

Carbon fiber is five times stronger than steel while being significantly lighter. This makes it ideal for electric vehicles, where reducing weight without compromising strength is essential.

Improved Energy Efficiency

Lighter vehicles consume less energy, which is particularly important for EVs. Carbon fiber helps reduce vehicle mass, leading to improved battery efficiency and longer driving range.

Enhanced Performance

Weight reduction translates to better acceleration, handling, and braking. Carbon fiber components improve overall vehicle dynamics, making EVs more responsive and enjoyable to drive.

Corrosion Resistance

Unlike metals, carbon fiber does not rust or corrode, making it ideal for long-lasting EV components, particularly in harsh weather conditions.

Design Flexibility

Carbon fiber composites can be molded into complex shapes, allowing for innovative designs and aerodynamic efficiency, which are crucial for modern electric vehicles.

4. Challenges in Adopting Carbon Fiber in Electric Vehicles

High Production Costs

One of the primary challenges of using carbon fiber is its high cost. Manufacturing carbon fiber components is expensive compared to traditional materials like steel and aluminum.

Manufacturing Complexity

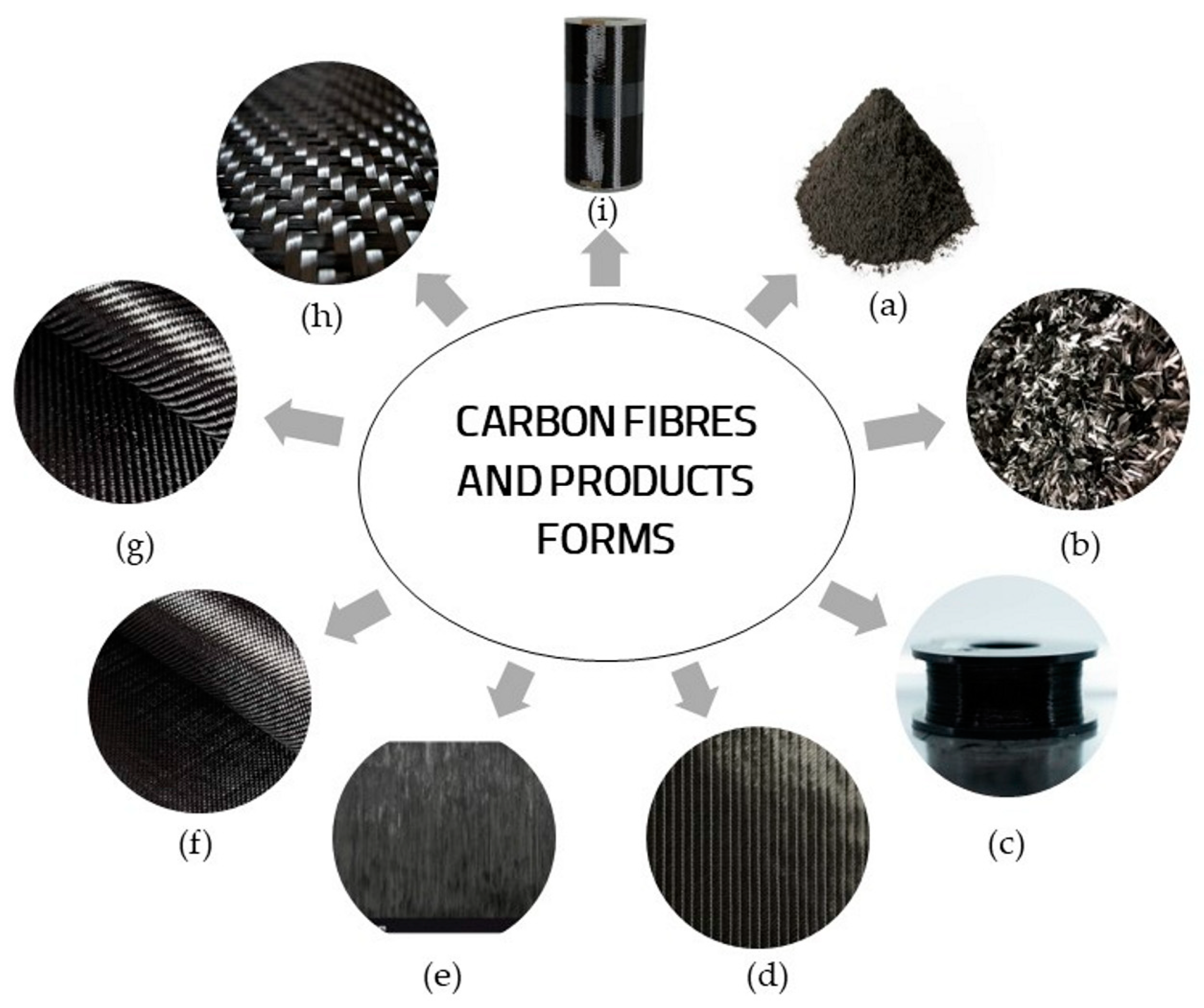

Carbon fiber production involves complex processes, including weaving, molding, and curing. These processes require specialized equipment and skilled labor, increasing production time and cost.

Recycling Challenges

Recycling carbon fiber composites is difficult compared to metals. Developing efficient recycling methods is crucial to making carbon fiber more sustainable for widespread EV use.

5. Future of Carbon Fiber in Electric Vehicles

Advancements in manufacturing techniques, cost reduction, and sustainability initiatives are expected to drive greater adoption of carbon fiber in electric vehicles. As battery technology improves, the demand for lightweight materials like carbon fiber will continue to grow.

Innovations such as hybrid composites, new resins, and automation in production processes will make carbon fiber more accessible to automakers, paving the way for a new generation of efficient, high-performance electric vehicles.

Conclusion

Carbon fiber’s unique properties make it an invaluable material for the electric vehicle industry. By reducing weight, improving efficiency, and enhancing performance, carbon fiber plays a pivotal role in the evolution of electric mobility. As technology advances, the integration of carbon fiber in electric vehicles will continue to expand, driving innovation and sustainability in the automotive industry.